Product Information Product Information |

|

| www.chinahanji.com |

|

|

HOME >> Equipment >> Lathed & milled equipment HOME >> Equipment >> Lathed & milled equipment |

|

Kehan Laser Micro-machining |

|

| |

1、Introduction

China Kehan Laser Company Limited specialized in developing and producing ultrafast laser CNC machine used in different area (as shown in the following pictures). This serial equipment are international top ranking high precision micro-nano cold working machines. They are equipped with high power ultrafast laser machine, laser scanning processing machine and high precision five-dimension CNC motion platform. Assembled by advancing CNC system, they are new high-tech products with ultra short-pulse laser, precision machinery, CNC technology and other technology. They are applied in equipment manufacturing industry, automobile and aerospace precision manufacturing industry and various micro processing industries. They can be used in incising, micro hole machining, marking, carving, lining and grooving difficult-to-machine material(such as cemented carbide, brittle glass, ceramics, organic polymer materials). |

|

|

|

|

|

|

| |

|

|

|

|

|

ultrafast laser CNC machine(a) |

|

ultrafast laser CNC machine(b) |

|

|

2、Laser Micromachining Products Introduction

|

|

|

|

|

|

|

| |

Application Area

Micromachining various metallic material

Processing Capability :

① Processing capability: Processing straight hole and bore-hole(positive hole and inverted cone hole);

② Thickness: in 3mm

③ Size: 50μm-1500μm

④ Machining Effect: Minimum edge heating. It means there is no slag phenomenon in the edge of the product.

⑤ Processing Precision: ±10μm

Potential Demand Marketing :

1、household appliance industry

2、engine, turbine industry

3、mechanical equipment, experimental apparatus industry

4、medical device industry

|

|

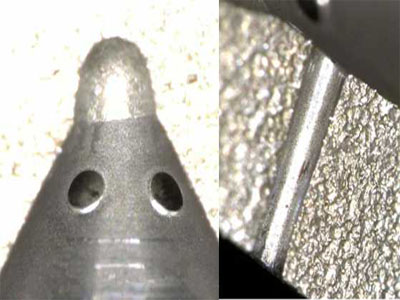

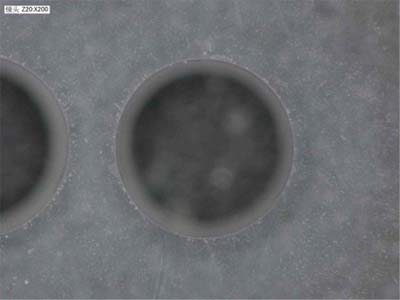

Sample Picture

a) Micro hole surface

b) Micro hole inwall

P-1 Φ220μm nozzle inverted cone hole |

|

|

|

|

|

|

| |

Application Area

Micromachining various metallic material

Processing Capability :

① Processing capability: Processing straight hole and bore-hole(positive hole and inverted cone hole);

② Thickness: in 3mm

③ Size: 50μm-1500μm

④ Machining Effect: Minimum edge heating. It means there is no slag phenomenon in the edge of the product.

⑤ Processing Precision: ±10μm

Potential Demand Marketing :

1、household appliance industry

2、engine, turbine industry

3、mechanical equipment, experimental apparatus industry

4、medical device industry |

|

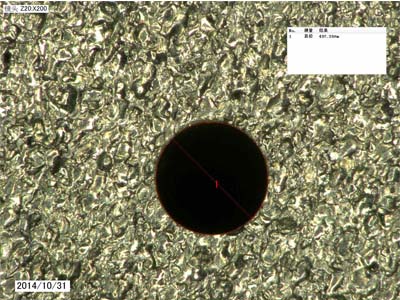

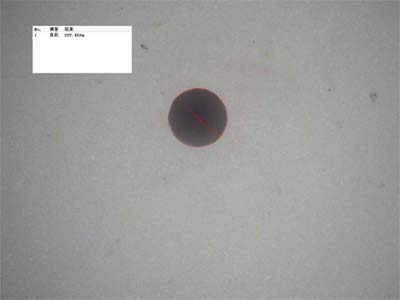

Sample Picture

P-2 Φ500μm straight hole |

|

|

|

|

|

|

| |

Application Area

Micromachining various metallic material

Processing Capability :

① Processing capability: Processing straight hole and bore-hole(positive hole and inverted cone hole);

② Thickness: in 3mm

③ Size: 50μm-1500μm

④ Machining Effect: Minimum edge heating. It means there is no slag phenomenon in the edge of the product.

⑤ Processing Precision: ±10μm

Potential Demand Marketing :

1、household appliance industry

2、engine, turbine industry

3、mechanical equipment, experimental apparatus industry

4、medical device industry |

|

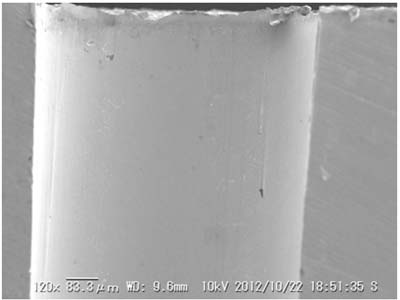

Sample Picture

P-3 Φ500μm inverted cone hole |

|

|

|

|

|

|

| |

Application Area

Micromachining various metallic material

Processing Capability :

① Processing capability: Processing straight hole and bore-hole(positive hole and inverted cone hole);

② Thickness: in 3mm

③ Size: 50μm-1500μm

④ Machining Effect: Minimum edge heating. It means there is no slag phenomenon in the edge of the product.

⑤ Processing Precision: ±10μm

Potential Demand Marketing :

1、household appliance industry

2、engine, turbine industry

3、mechanical equipment, experimental apparatus industry

4、medical device industry |

|

Sample Picture

P-4 Φ500μm Electron micrograph of straight hole section |

|

|

|

|

|

|

| |

Application Area

Micromachining non-metallic material: quartz, sapphire, silicon wafer

Processing Capability :

①Processing capability: Processing straight hole and bore-hole(positive hole and inverted cone hole);

②Thickness: in 2mm

③Size: 50μm-1500μm

④Machining Effect: Minimum edge heating. It means there is no slag phenomenon in the edge of the product.

⑤Processing Precision: ±10μm

Potential Demand Marketing :

1、solar energy industry

2、electron industry

3、optical industry

4、photovoltaic industry |

|

Sample Picture

P-5 Φ300μm micro hole in sapphire substrate |

|

|

|

|

|

|

| |

Application Area

Micromachining non-metallic material: quartz, sapphire, silicon wafer

Processing Capability :

①Processing capability: Processing straight hole and bore-hole(positive hole and inverted cone hole);

②Thickness: in 2mm

③Size: 50μm-1500μm

④Machining Effect: Minimum edge heating. It means there is no slag phenomenon in the edge of the product.

⑤Processing Precision: ±10μm

Potential Demand Marketing :

1、solar energy industry

2、electron industry

3、optical industry

4、photovoltaic industry |

|

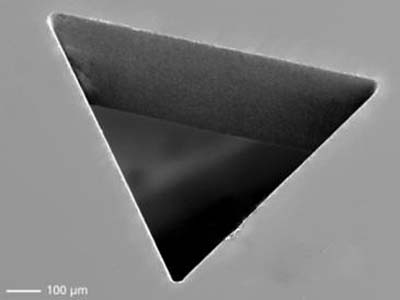

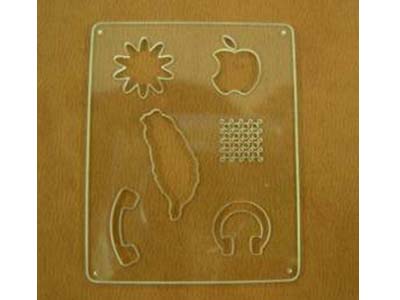

Sample Picture

P-6 Incising sapphire with thickness 0.3mm |

|

|

|

|

|

|

| |

Application Area

Micromachining non-metallic material: quartz, sapphire, silicon wafer

Processing Capability :

①Processing capability: Processing straight hole and bore-hole(positive hole and inverted cone hole);

②Thickness: in 2mm

③Size: 50μm-1500μm

④Machining Effect: Minimum edge heating. It means there is no slag phenomenon in the edge of the product.

⑤Processing Precision: ±10μm

Potential Demand Marketing :

1、solar energy industry

2、electron industry

3、optical industry

4、photovoltaic industry |

|

Sample Picture

P-7 Punching in sapphire(Φ800μm) |

|

|

|

|

|

|

| |

Application Area

Glass micromachining: soda-lime glass, coated glass, Corning Gorilla Glass and so on

Processing Capability :

①Processing capability: Processing straight hole and bore-hole(positive hole and inverted cone hole);

②Thickness: in 2mm

③Size: 100μm-1500μm

④Machining Effect: Minimum edge heating. It means there is no slag phenomenon in the edge of the product.

⑤Processing Precision: ±10μm. Edge damage controlled quantity<100um.

Potential Demand Marketing :

1、solar energy industry

2、electron industry

3、optical industry

4、photovoltaic industry |

|

Sample Picture

P-8 Drilling and incising in glass |

|

|

|

|

|

|

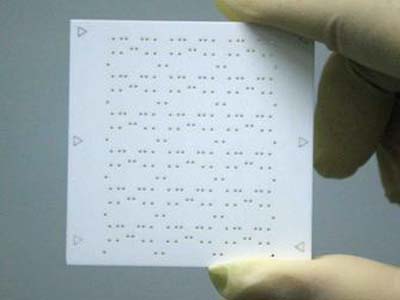

| |

Application Area

Micromachining ceramic material: 75,95,96,99aluminum oxide ceramics, aluminium nitride, carborundum, metallization ceramics and so on

Processing Capability

① Processing capability: Processing straight hole and bore-hole(positive hole and inverted cone hole);

② Thickness: in 2mm

③ Size: 100μm-1500μm

④ Machining Effect: Minimum edge heating. It means there is no slag phenomenon in the edge of the product.

⑤ Machining Effect: The edge is burr-free, with high surface finish. Heat effect area is small.

Potential Demand Marketing :

1、electron industry

2、photovoltaic industry |

|

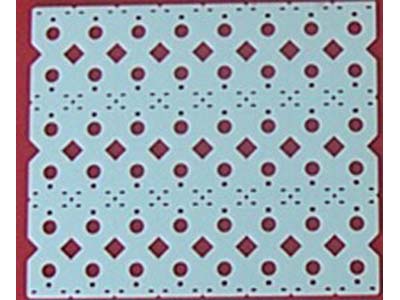

Sample Picture

|

|

|

|

|

|

|

| |

Application Area

Micromachining ceramic material: 75,95,96,99aluminum oxide ceramics, aluminium nitride, carborundum, metallization ceramics and so on

Processing Capability

① Processing capability: Processing straight hole and bore-hole(positive hole and inverted cone hole);

② Thickness: in 2mm

③ Size: 100μm-1500μm

④ Machining Effect: Minimum edge heating. It means there is no slag phenomenon in the edge of the product.

⑤ Machining Effect: The edge is burr-free, with high surface finish. Heat effect area is small.

Potential Demand Marketing :

1、electron industry

2、photovoltaic industry |

|

Sample Picture

|

|

|

|

|

|

|

| |

Application Area

Micromachining ceramic material: 75,95,96,99aluminum oxide ceramics, aluminium nitride, carborundum, metallization ceramics and so on

Processing Capability

① Processing capability: Processing straight hole and bore-hole(positive hole and inverted cone hole);

② Thickness: in 2mm

③ Size: 100μm-1500μm

④ Machining Effect: Minimum edge heating. It means there is no slag phenomenon in the edge of the product.

⑤ Machining Effect: The edge is burr-free, with high surface finish. Heat effect area is small.

Potential Demand Marketing :

1、electron industry

2、photovoltaic industry |

|

Sample Picture

P-9 Drilling and incising in ceramic |

|

|

|

|

|

|

| |

Application Area

Micromachining organic materials

Processing Capability

① Processing capability: Processing straight hole and bore-hole(positive hole and inverted cone hole);

② There is almost no heat effect in the edge.

③ Thickness: in 1mm

④ Size: 100μm-1500μm

⑤ Processing Precision: ±10μm

Potential Demand Marketing :

1、mobile phone industry

2、apparatus industries |

|

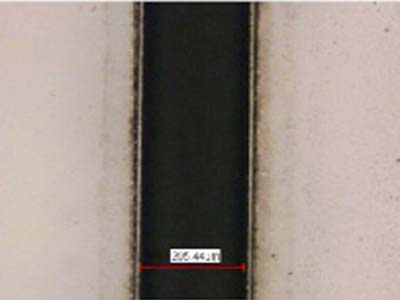

Sample Picture

|

|

|

|

|

|

|

| |

Application Area

Micromachining organic materials

Processing Capability

① Processing capability: Processing straight hole and bore-hole(positive hole and inverted cone hole);

② There is almost no heat effect in the edge.

③ Thickness: in 1mm

④ Size: 100μm-1500μm

⑤ Processing Precision: ±10μm

Potential Demand Marketing :

1、mobile phone industry

2、apparatus industries |

|

Sample Picture

P-10 Drilling and incising in organic materials |

|

|

3、Laser Micromachining Vedio

|

|

|

|